Processes and Materials

Overview of our Capabilities

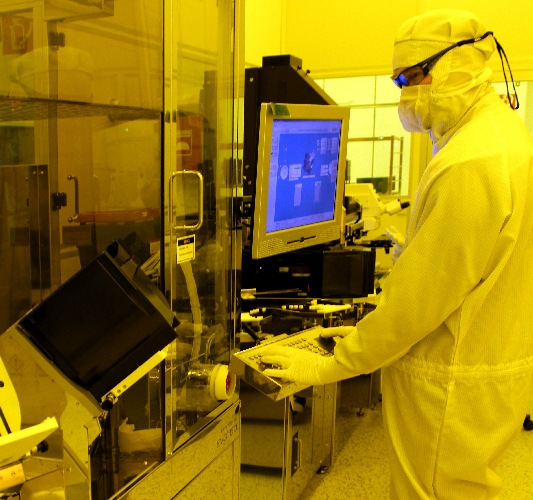

Lithoglas operates wafer fab cleanrooms offering a broad range of equipment and material capabilities.

- Cleanroom Class 10 and 1000

- Wafer Sizes: 200mm, 150mm, 100mm (not supported in all processes)

- Wafer Cleaning (wet, dry)

- Wet Etching of Silicon and Glass

- Laser Structuring of Borosilicate and Silica Glasses

- CD Microscopes, Automatic Optical Inspection, Thickness Measurement, Profilometer

- PVD Deposition of SiO2 and Al2O3

- Lithography – Spin-On and Spray Resist Coating (positive and negative tone)

- Lithography – Mask Alignment (front and backside, 2 mic resolution)

- Wafer Bonding (Anodic and Fusion)

- Metal Deposition of Al, Cr, CrNi, Au, WTi

- Thermal Oxide Deposition

- LPCVD and PECVD Silicon Nitride deposition

- Wafer Dicing